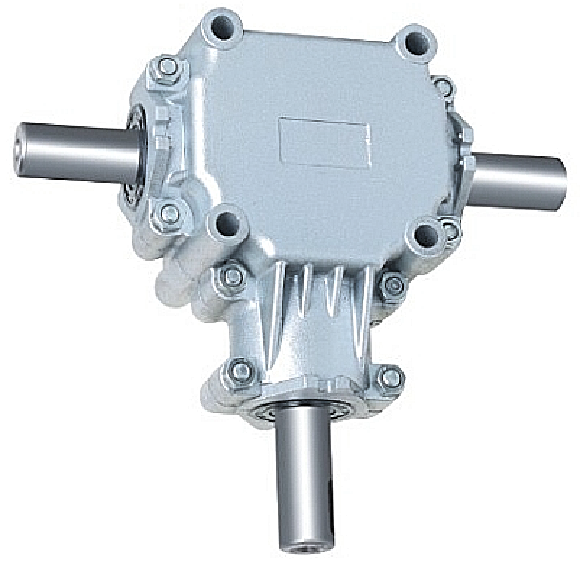

Product Description

1. Description:

| Part No.: | 1629534 |

| Machine No.: | D8R D8N SPROCKET |

| Description: | Sprocket |

| Logo: | Beneparts |

| Surface Hardness | 52 ~ 58 |

| Color: | Yellow or others |

| Production Method: | Casting / Forging |

| Material: | 40Mn |

2. Our products range

3. Our production line:

4.Popular items blow for reference:

| Brand | Model | |||

| Track Roller, Top Roller, Sprocket, Idler, Track Link, Track Shoes | ||||

| PC18-2 | PC20-5/7 | PC30-5/6/7/8 | PC40-5/6/7 | |

| PC50/PC55 | PC60-5/6/7 | PC100-5/6/7 | PC120-5-6-7 | |

| PC200-3/5/6/7/8 | PC220-3/5/6/7/8 | PC200LC-3/5/6/7/8 | PC220-3/5/6/7/8 | |

| PC300-5-6-7 | PC300LC-/5-6-7 | PC350-5/6/7 | PC350LC-5/6/7 | |

| PC360-5/6/7 | PC360LC-5/6/7 | PC400-1/3/5/6/7 | PC400LC-1/3/5/6/7 | |

| PC450-5/6/7 | PC450LC-5/6/7 | PC600 | PC800 | |

| EX30 | EX40 | EX55 | EX60-2/3/5 | |

| EX70 | EX100-1/3/5/ | EX120-1/3/5 | EX150 | |

| EX200-1/2/3/5 | EX200LC-1/2/3/5 | EX220-1/2/3/5 | EX220LC-1/2/3/5 | |

| EX270-1/2/5 | EX270LC-1/2/5 | EX300-1/2/3/5 | EX300LC-1/2/3/5 | |

| EX330 | EX330LC | EX400-1/2/3/5 | EX400LC-1/2/3/5 | |

| EX450-1/2/3/5 | EX450LC-1/2/3/5 | UH07-7 | UH081 | |

| UH083 | UH045 | UH571 | ||

| ZAX55 | ZAX70 | ZAX120 | ZAX200 | |

| ZAX210 | ZAX230 | ZAX240 | ZAX330 | |

| ZAX450 | ||||

| DH55 | DH80 | DH130 | DH150 | |

| DH220 | DH258 | DH280 | DH300 | |

| DH320 | DH360 | DH370 | DH400 | |

| DH420 | DH500 | |||

| DX300 | DX370 | DX380 | ||

| SK035 | SK035SR | SK30 | SK35 | |

| SK45 | SK50-1 | SK50-6 | SK55 | |

| SK60-3 | SK60-1/2/5 | SK60-8 | SK100 | |

| SK120 | SK130-8 | SK200-3/5/8 | SK210 | |

| SK230 | SK250 | SK300 | SK320 | |

| SK330 | SK350 | SK07N2 | ||

| SH35 | SH55 | SH60 | SH65 | |

| SH75 | SH100 | SH120 | SH120A3 | |

| SH200 | SH220 | SH265 | SH280 | |

| SH300 | SH320 | SH340 | SH350 | |

| SH430 | LS2800 | |||

| HD250 | HD400 | HD450 | HD700 | |

| HD770 | HD820 | HD1571 | HD1250 | |

| HD1430 | ||||

| R55 | R60-5/7/8 | R80 | R130 | |

| R150LC-7 | R200 | R210-3 | R220-5 | |

| R225-7 | R275 | R290 | R300 | |

| R320 | R305 | R360 | R450 | |

| R914 | R924 | R934C | R944C | |

| CX35 | CX45 | CX55 | CX240 | |

| KX35 | KX50 | KX55 | KX80 | |

| KX185 | ||||

| SWE35 | SWE40 | SWE50 | SWE55 | |

| SWE60 | SWE70 | SWE85 | SWE330 | |

| IHI30 | IHI35 | IHI80 | IHI85 | |

| TB150 | TB175 | |||

| FR65 | FR85 | |||

| SY65 | SY200 | SY215 | SY330 | |

| YC13 | YC35 | YC45 | YC60 | |

| YC85 | YC135 | |||

| VIO30 YM30 | VIO35 YM35 | VIO40 YM40 | VIO55 YM55 | |

| VIO75 YM75 | ||||

| D3B D3C | D4 | D4D | D4E | |

| D4H | D5 | D5B | D5C | |

| D5H | D5M | D5N | D6 | |

| D6C | D6D | D6R | D6H | |

| D6T | D7G | D7R | D7H | |

| D8N | D8L | D8T | D8R | |

| D8H | D8K | D9L | D9N | |

| D9R | D9T | D10N | D10R | |

| D10T | D11N | D11R | ||

| D20 | D31 | D37EX-21 | D40 | |

| D41P-6 | D41E-6 | D50 | D53 | |

| D51EX-22 | D60 | D65 | D65-12 | |

| D61EX-12 | D65EX-12 | D65PX-12 | D80 | |

| D85 | D85EX-15 | D85-21 | D155 | |

| D155A-1 | D155A-2 | D155A-3 | D155A-5 | |

| D155-6 | D275 | D355A-3 | D375-5 | |

| BD2G | ||||

| MODEL |

| EX15/15-2/17U |

| EX100-1/2/3,EX120/ZX130/JD490E |

| EX135 |

| EX200-1/FH200-3 |

| EX200-2/EX220/EX220LC-1/-2-3/-5/ZX225/ZX230LC |

| EX160-5,EX200-3/-5, ZX160/180/200/210,EX225LC |

| EX215E/EX235/EX255 |

| EX300-1/EX270 / EX300 / JD892D LC |

| EX300-5,ZX270/280/330-1/350,JD270/330/350 |

| EX400-3/5,EX400 /JD992D+E |

| EX550,EX600,ZX500LC/ZX600/ZX650H |

| EX700/EX750-5/EX800H-5/ZX670LCH/ZX800/ZX850-3/ZX 850LC-3/ZX870LC-3 |

| UH03M/045-7/063 |

| UH035-7/UH043/UH04-3/UH051 |

| UH06-5/UH07-3/5/7,UH081/082/83/09-7/UH101,E215B/225,JS200,HD700,K907,MS180 |

| ZX25 |

| ZX50 |

| ZX70-3 |

| ZX135 |

| ZX200-3,210,220 |

| ZX240-3/ZX250 |

| ZX270-3 |

| ZX330-3 |

| EX1100 |

| EX1800 |

| ZX650H |

| ZX370 LCHGI |

| E70,E70B |

| E110B/E120B,E311/312/313/314 |

| E120B |

| E200B/EL200B |

| E215DLC/933R,JCB:208/32002 |

| E240/EL240B |

| E300B,EL300B |

| E301.5,301.6,301.8,301.6C,301.8C |

| E303.5(21+/9b-12m) |

| E303CR(21+/9b-12m) |

| E303CCR |

| E305.5 |

| E307,307B,308B |

| E307D,308D,21+/15b |

| E315/317/318,CX160/CX160B/CX250 |

| E320/E320L/E322/E322N/E315/318 |

| E325/E325L |

| E330/E330/E336 |

| E345,345B |

| E350 |

| D3-D3B-R |

| D4,LK49 |

| D4C/D4D/D4E/941 |

| D57,KM782 |

| CAT225B/CAT225 |

| 215/225(RIM)(225-5) |

| 235-7R |

| R140-7 |

| R210-3/R210LC-3 / SE210LC-2 |

| R245-7,R260-7 |

| R225LC-7/R210-7/R250-7 |

| R290LC-7/R305LC-7R320LC-7 |

| R375LC-7,R360LC-3/7 |

| R455LC-7,R450LC-3/7 |

| DH50,DH55 |

| DH120/DH130/DH150/S130-3/-5/S140-V |

| DH220 |

| DH220-3 |

| DH220-5/7,DH225-7/9(30H)S220-5/DX220 |

| DH258-5(26H) |

| DH280 |

| S290LC-3 |

| DH290-5/S290-5 |

| DH370/420 |

| DH450-3,S450-3/S470LC-5 |

| S500-LC(24H) |

| DX300/340 |

| D20-5 |

| PC12R/12R-8/15R/15R-8 |

| PC30,PC35 |

| PC40-7,R45 |

| PC60-6/PC60-7 |

| PC100-5/120-5,6 |

| PC120.06 |

| PC160-6/PC180-6 |

| PC200-2/PC220-1/2 |

| PC150/160/180,PC200-5/PC210-5,-7-8/PC220-5,-6,-7,PC228/PC230-6/PC240-5,-6 |

| PC300-3/5/PC300/280-3 |

| PC300-6/7/8,PC360-7 |

| PC400-3/5/PC400 |

| PC380LC-6,PC400-6/-7,PC450-6/-7 |

| PC650 |

| PC1250-7 |

| PC1600 |

| D31P-16,17,18/D37E-1,D37P-1,-2,-5 |

| D31PX-21 |

| D41-6(171) |

| SK25SR-2 |

| SK30SR-2,SK35SR-2,CX31(B),CX36 |

| SK40SR,SK45SR-2,CX47 |

| SK55 |

| SK100/SK115SR/SK04N2/SK120/SK120LC-3/SK130SR/SK135SR-1 |

| SK150LC-3/SK160LC-3/SK210LC-3 |

| SK200-3/SK200-5 |

| SK200-8 |

| SK230-6 |

| SK260-8 |

| SK330,SK350-8 |

| SK480/SH400-3 |

| MS180-3,6 |

| MS140-8 |

| EC25,EC35,EB350 |

| EC55 |

| EC135LC EC140/SE130LC-3 |

| EC225,SE210LC-2 / R210 /EC210 /R210LC-3/MX222 |

| EC230B |

| EC240,EC255,SE210LC-3 |

| EC295,MX295 EC290LC |

| EC360,SE350LC-2,-5,MX14-2,MX352 |

| EC420/H16D/H16DLC,MX16 |

| EC460,SE450LC-2,MX452 |

| EC460B |

| MX8 |

| MX8-2 |

| MX55 |

| MX6LC,SE130LC-2/MX132/R130LC-3 |

| MX132LC |

| MX132LC |

| MX222 |

| MX292,SE280LC-2, R290(81E5-2001)/MX295(24H) |

| EC55 |

| EC135LC EC140/SE130LC-3 |

| EC225,SE210LC-2 / R210 /EC210 /R210LC-3/MX222 |

| EC230B |

| EC240,EC255,SE210LC-3 |

| EC295,MX295 EC290LC |

| EC250D,EC250E,EC300D,EC300E |

| MA10 |

| MA12 |

| MX3,SE25 |

| EC210B, EC140E LM EC220E |

| EC480 |

| EC700 |

| EC700 |

| SH100/120,LS2650Q/SH120 /CASE9571B KNA0343 |

| SH200,LS2800Q / CASE9030B/9040B/CX210/225/240 |

| SH300,LS3900Q/LS4300Q/CASE9050B |

| SH800-3,CX800 |

| TD15C-R |

| TD20E-R/D87E |

| SY215 |

| B27/B27V |

| VIO45/VIO50,B5/B50 |

| VIO55-6B |

| YC60 |

| HD820(22hole/26hole) |

| U25 |

| KX36/36-2/41-2/41-3V |

| KX71-3/KX91-3 |

| KX71-3S,KX91-3S2,U35S2 |

| KX121-3,KX121-3s |

| KX080-3,KX080-3T,KX080-4 |

| SVL75 |

| SVL90 |

| TB125 |

| TB250 |

| TB070 |

| PR721/PR721B |

| R911/921/925,JCB208/32002 |

| R900C/R912STD |

| R952HD/R961B/R962LC/R965B |

| R941 |

| R932HDSL |

| VR385710 |

| VQ322000 |

| JS70/JZ70 |

| JS130/JS130LC/JS140 |

| JS330LC/JS330NLC |

| JS460L |

| 807LC |

| FL4 |

| FD14//FD175/FL14D/FL14E/FP40 |

| 70C |

| FL10/FL10C |

| F25-55-75CF |

| F25-55-75CM |

| FL4-72-85CM |

| FH95 |

| CF65 |

| C95 |

| C90 |

| CF60 |

| CRD25 DRILLING |

| W1000/1200/1300/1500 /1900 |

| W2000 |

| JD450G-B |

| JD650G |

| JD790 / JD790LC/EX200 |

| JD790D / JD790E/EX200-2 |

| 892D LC / EX300-1 |

5. Our warehouse:

6.Company information

HangZhou CZPT Machinery co., Ltd as your reliable Undercarriage parts supplier, offering full range of replacement parts suitable for all kinds of earthmoving machines which apply to mining, construction, agriculture etc. Like Excavator, Bulldozer, Loader, Backhoe, Scraper, Crusher and so on. The replacement parts that we supply including casting parts like idler, sprocket, top roller, track link, track roller, track shoes…, etc. and forged parts like forged idler, sprocket, top roller, track link, track roller, track shoes…, etc.

Beneparts has a very strong sales team and firmly cooperated manufacturer with high-tech and focus on quality with more than 28 years experience.

Our advantages are 4 fold, our:

1.strong technical team, and we have the ability to formulate materials to meetthe specific needs of our customer’s projects.

2.Perfect quality monitoring system, and full range of advanced facilities, like Component analysis machine, Impact Machine, Tensile Strength machine etc.

3. Rich experience to do OEM/ODM business, we can develop items as per drawings and samples if you have specific requirement.

4. Efficient management, we can short delivery time and we have good after sale service which keep long term business cooperation with our customers.

Our commitment to you is always providing quick, convenient, effective customer service.

Look CZPT to meeting you!

| Type: | Sprocket |

|---|---|

| Application: | Excavator |

| Certification: | CE |

| Condition: | New |

| Machine No.: | D8r D8n |

| Production Method: | Casting / Forging |

| Customization: |

Available

| Customized Request |

|---|

Proper Installation and Alignment of Segment Sprockets for Optimal Performance

Proper installation and alignment of segment sprockets are essential to ensure optimal performance, smooth power transmission, and extended sprocket life. Here’s a step-by-step guide on how to install and align segment sprockets:

- Clean the Shaft and Sprocket: Before installation, make sure the shaft and the segments of the sprocket are clean and free from any debris or contaminants that could interfere with the proper seating of the segments.

- Check the Fit: Verify that the segment sprocket matches the shaft’s size and fits securely onto the shaft. The segments should have a snug fit without any play or excessive clearance.

- Assemble the Segments: Carefully assemble the segments onto the sprocket hub, ensuring they interlock correctly. Follow the manufacturer’s guidelines for the proper assembly process to avoid any misalignment.

- Position the Sprocket: Place the assembled sprocket onto the shaft, making sure it is positioned correctly according to the manufacturer’s specifications or engineering drawings.

- Check Alignment: Use alignment tools or techniques to verify that the sprocket is aligned properly with the conveyor chain or belt. Proper alignment ensures that the sprocket teeth mesh smoothly with the chain or belt, reducing wear and enhancing power transmission efficiency.

- Adjust Position if Necessary: If the sprocket is not aligned correctly, make necessary adjustments to ensure proper positioning. This may involve moving the sprocket along the shaft or using shims for precise alignment.

- Tighten Bolts: Once the sprocket is aligned, tighten the bolts securely to hold the segments in place. Use the manufacturer’s recommended torque values for the bolts to prevent over-tightening or under-tightening.

- Perform a Trial Run: After installation, conduct a trial run of the conveyor system or equipment to check for any issues, unusual noises, or misalignment. Monitor the sprocket’s performance during this trial period.

- Regular Maintenance: Implement a regular maintenance schedule to inspect and lubricate the segment sprockets. Check for signs of wear, fatigue, or damage during these inspections and replace any worn or damaged segments promptly.

Proper installation and alignment of segment sprockets contribute to the smooth and efficient operation of conveyor systems and machinery. Misaligned sprockets can lead to premature wear, increased friction, and reduced power transmission efficiency, affecting the overall performance of the system.

If you are unsure about the installation and alignment process, consult with the sprocket manufacturer or seek advice from industry experts to ensure you achieve the best results and optimal performance from your segment sprockets.

Identifying Signs of Wear, Fatigue, or Damage in Segment Sprockets

To ensure optimal conveyor performance and prevent potential failures, it is essential to regularly inspect segment sprockets for signs of wear, fatigue, or damage. Here are some indicators to look out for:

- Tooth Wear: Check for signs of wear on the sprocket teeth. Excessive wear may lead to a mismatch with the chain or belt, affecting the smooth motion of the conveyor system.

- Cracks or Fractures: Inspect the sprockets for any visible cracks or fractures, as these can compromise the sprocket’s structural integrity and lead to catastrophic failure.

- Deformation: Look for any signs of deformation or bending in the sprocket body. Deformed sprockets may cause chain misalignment and affect the conveyor’s overall performance.

- Corrosion: In corrosive environments, check for signs of rust or corrosion on the sprocket surface. Corrosion can weaken the sprocket and reduce its lifespan.

- Excessive Noise or Vibration: Unusual noises or vibrations during conveyor operation can indicate issues with the sprockets. Investigate the source and address any problems promptly.

- Chain or Belt Wear: Monitor the condition of the chain or belt that interfaces with the sprockets. Excessive wear on the chain or belt may be a sign of problems with the sprockets.

- Poor Conveyor Performance: If the conveyor system experiences frequent jams, misalignment, or slowdowns, the sprockets could be a potential cause. Investigate and resolve the issues as needed.

When to Replace Segment Sprockets:

The replacement schedule for segment sprockets depends on various factors, including the operating conditions, maintenance practices, and the specific material used in the sprockets. As a general guideline:

- Regularly scheduled maintenance: Incorporate sprocket inspections into routine maintenance tasks to identify any signs of wear or damage early on.

- Replace worn or damaged sprockets: If any signs of wear, fatigue, or damage are detected during inspections, promptly replace the affected sprockets to prevent further issues.

- Follow manufacturer recommendations: Adhere to the manufacturer’s guidelines regarding sprocket replacement intervals and maintenance procedures.

- Consider environmental factors: In harsh environments or high-temperature applications, sprockets may require more frequent replacement due to accelerated wear.

- Monitor performance: If the conveyor system experiences frequent breakdowns or reduced efficiency, assess the condition of the sprockets and consider replacement if necessary.

Regular inspection, maintenance, and timely replacement of worn or damaged segment sprockets are crucial for the smooth and reliable operation of the conveyor system.

What is a Segment Sprocket, and How Does it Differ from Traditional Sprockets?

A segment sprocket, also known as a split sprocket or split rim sprocket, is a specialized type of sprocket design that differs from traditional solid sprockets in its construction and application. The main difference lies in the way the sprocket is assembled and mounted onto the shaft.

Key Characteristics of Segment Sprockets:

- Split Design: The segment sprocket is made up of two or more individual segments that fit together around the shaft. These segments can be split in half or divided into multiple pieces, allowing for easy installation and removal without disassembling the entire shaft or conveyor system.

- Mounting Mechanism: The segments of the sprocket are secured onto the shaft using bolts, clamps, or other fastening methods. This mounting mechanism provides a secure grip on the shaft while still allowing quick and convenient assembly and disassembly.

- Adjustable Positioning: The segment sprocket’s split design allows for adjustable positioning along the shaft, enabling fine-tuning of the sprocket’s alignment with the roller chain or belt. This adjustability helps optimize power transmission and reduce wear on the chain or belt.

- Wide Applicability: Segment sprockets are commonly used in applications where frequent sprocket replacement or adjustments are required. They are particularly useful in conveyor systems, where access to the shaft is limited or when the conveyor’s design may change over time.

Advantages of Segment Sprockets:

- Easy Maintenance: The split design of segment sprockets simplifies maintenance tasks as they can be replaced or adjusted without fully disassembling the system, reducing downtime and labor costs.

- Quick Installation: The ability to mount the sprocket segments onto the shaft individually speeds up the installation process compared to traditional sprockets that require sliding over the end of the shaft.

- Cost-Effective: In applications where frequent sprocket replacement is necessary, using segment sprockets can be cost-effective over time due to reduced maintenance efforts and extended equipment lifespan.

- Alignment Flexibility: The adjustable positioning of segment sprockets allows for precise alignment with the roller chain or belt, minimizing chain or belt wear and ensuring efficient power transmission.

It’s important to note that while segment sprockets offer advantages in certain applications, they may not be suitable for all scenarios. In high-speed or heavy-duty applications, traditional solid sprockets may be preferred for their robustness and higher load-carrying capacity.

In summary, a segment sprocket is a specialized type of sprocket designed for easy assembly, maintenance, and alignment. Its split construction allows for quick installation and adjustments, making it ideal for applications where accessibility and frequent sprocket changes are essential.

editor by CX 2023-11-14

Ensign made in China – replacement parts – in Gaya India Brand 50 HP Farm Tractor for Sale with ce certificate top quality low price

We – EPG Group the bigge EPT Chain and agricultural gearbox manufacturing unit in China with 5 diverse branches. For more information: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

YX504D-B

Sturdy Electrical power

Effectively-recognized manufacturer motor is adopted with big torque reserve and strong electrical power

Optimized energy emission and functionality with reduced fuel consumption and higher trustworthiness

Superior Technologies

8F+2R compound spur gear transmission is utilized with reasonable gear match. Mechanical variable speed change with minimal sounds and massive transmission torque.

Smaller sized measurement with brief wheel foundation and compact structure is much more adaptable to regions like greenhouse and orchard.

Higher Adaptability

Wheel tread of the rear whee EPT is action-much less adjustable and can be fulfill the necessity of diverse line spacing for different crops.

Double pace power get-off. Two independent PTO combinations (720/850r/min and 540/720r/min) are different, generating it adaptable to numerous doing work websites.

Easy Procedure

Dry kind single-action clutch, which is effortless to function

Complete hydraulic steering tends to make running adaptable.

YX554-C/YX604-C/YX704-C

EPT Electricity Performance

Quanchai engine is of common configuration and Xinchai motor is optional. Torque reserve of the engines are massive and electricity is sturdy.

Electricity emission and efficiency are upgraded with low gasoline consumption, high dependability and advanced technological innovation.

Cozy, Inventive and Xihu (We EPT Lake) Dis.nized Style

EPT streamline layout of the tractor entire body and eye-catching look.

Flat floor, suspend pedal, Side-positioned running stages

, double motion clutch and complete hydraulic steering method make the procedure simple and versatile.

Shock absorption floor is employed. Magnificent shock absorption taxi is optional. Sealing is very good and sound is reduced.

Smart and High-efficient Travel Technique

12F+12R equipment change is easy and versatile for running. Pace match is affordable and doing work efficiency is higher.

Synchronizer shifting is optional for effortless & flexible running and failure price is minimal.

Reinforced shut front axles with high reliability.

Reliable and Secure Doing work Products

High reliability force level altering elevator is employed, and strong force elevator is optional.

EPT output is optional. Substantial productive perform can be carried out in various farmlands and transportation functioning internet sites.

PTO 540/720r/min is common. And 540/1000r/min or 760/1000r/min is optional. Numerous agricultural doing work products can be geared up.

| Design | YX504D-B | |

| Travel Type | 4wd | |

| Motor | Rated Energy(kw) | 36.8 |

| Rated Speed(r/min) | 2400 | |

| Oil EPT Program | digital VE pump | |

| General dimension L*W*H(mm) | 3480X1400X1450 | |

| (kg)Min.Functioning weight | 1550 | |

| Tire Specification | six.00-fourteen/13.6-16 | |

| Transmission Sort | Mechanical stage velocity change | |

| Gears(ahead/reverse/creeper) | 8F+2R | |

| wheel track | Front(mm) | 1100 |

| Rear(mm) | 1050 | |

| wheel foundation(mm) | 1850 | |

| (r/min) PTO shaft speed |

720/850 optional:540/720 | |

Our business:

Why choose us?

one). The quality is guaranteed owing to powerful specialized assistance ,substantial quality element ,superior generation line and rigid quality manage technique.

2). 1-stop service with a big spare components warehouse and skilled provider crew .No matter the place you are, you are guaranteed of Ensign’ s warm reception, dependable and effective expert services and persistent care.

EPT phrases:

1). Shipping and delivery: thirty times for typical orders

two). Value: We have price on foundation FOB HangZhou and CIF or CFR your vacation spot for your decision

three). Payment phrases for fir EPT get:

—–T/T thirty% down payment and stability prior to cargo

—–a hundred% L/C at sight

four). Payment for long phrases cooperation of excellent reputation partners, we have SINOSURE or Euler Hermes insurance for our VIP consumers, and we can provide credit rating provider following we common with every other. We are seeking for partnership for long-time period enterprise

The use of unique equipment manufacturer’s (OEM) portion figures or trademarks , e.g. CASE® and John Deere® are for reference functions only and for indicating item use and compatibility. Our organization and the detailed alternative areas contained herein are not sponsored, accepted, or created by the OEM.

Custom shop made in China – replacement parts – bondioli pto shaft OEM Japanese Tractor Parts Standard Gears Supplier with ce certificate top quality low price

We – EPG Group the greatest agricultural gearbox and pto manufacturing unit in China with 5 diverse branches. For far more information: Cell/whatsapp/telegram/Kakao us at: 0086-13083988828

acura mdx travel shaft Our tractor push shaft factory freelander generate shaft substitution has jeep jk rear driveshaft received 1 3/8 6 spline pto yoke the bush hog sq720 pto shaft certification tractor pto shaft standards of gsp cv shafts China’s 2006 ford f150 generate shaft Farm pto shafts ebay Machinery Merchandise High quality Authentication promulgated by the Farm Equipment Products Top quality Authentication Centre of China. EPG is prepared to cooperate sincerely and build frequently with close friends! We produced and made many tractor spare areas for Japanese Tractors&time period

The areas for example&colon Tyres&comma rim Jante&comma Kit coupling KB-TX 3 point linkage&period Exhaust pipe Steering wheel&period of time Package coupling YM F14&solF15 ect&time period

Most of the spare areas are with inventory&period of time If you are interested in&comma make sure you come to feel straightforward to contact me&interval

| Japanese tractor spare components in Stock | |

| tractor rim | gears |

| kit coupling | bearing |

| steering wheel | tractor url hitch |

| PTO shaft | tractor sealing KB-TX |

| tractor blades | lamps |

| tractor hitch YM F14&solF15 | link hitch |

| tyre | sealing |

| gasket | light |

| air filter | tractor hub |

| filter element | brake shoes |

| air strainer element | calande |

| air filter cartridge | hitch |

| cardan | tractor ignition key |

| tractor drinking water pipe | klaxon |

| disc clutch KB-TX | mass tractor |

| counter | battery cap |

| clutch | ratchet wheel |

| tractor bulb | oil pressor |

| tractor light | radiator cap |

| exhaust collector | tractor regulator |

| Tractor keys | stickers |

| gasket | light |

| tractor blades | lamps |

Rewards of our company—HangZhou Lefa

one&period of time Specializing in production and marketing the farm equipment far more than eleven many years&time period

two&period of time “Lefa” create in China and France&interval

3&period “CE”& “Provider Evaluation Certificate”

four&interval With the strict top quality handle and best service for customers&period

5&interval We can provide outstanding and quick after-product sales service&time period

six&period Our intention&colon Win-win&time period

7&time period We can design and style and generate devices in accordance to customer’s demands&period of time

8&time period We created dozens of Japanese tractors components&comma we can deliver the parts with machine together&interval

Welcome to send out us your inquiry&period of time We will ship you the detail list with images&interval

Welcome to visit our manufacturing unit&excl

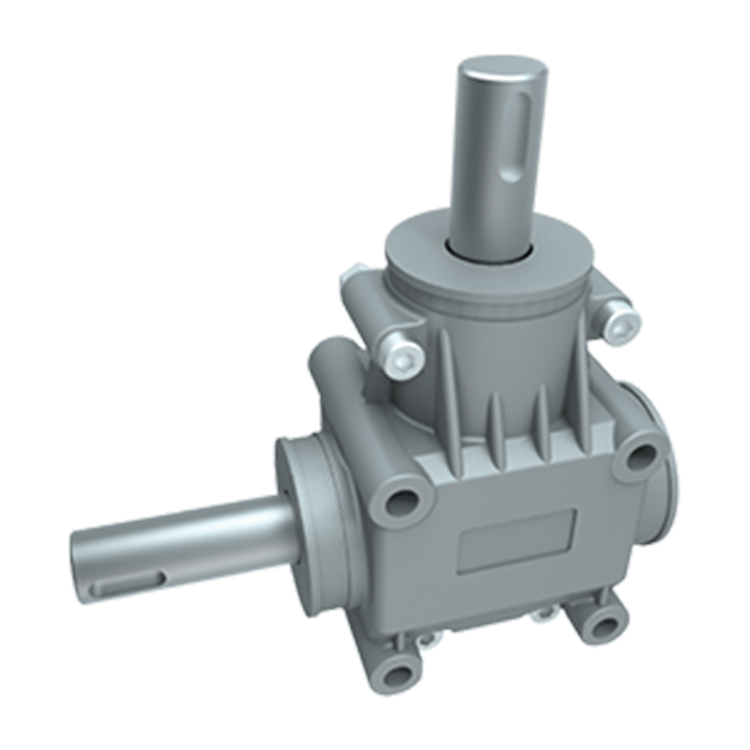

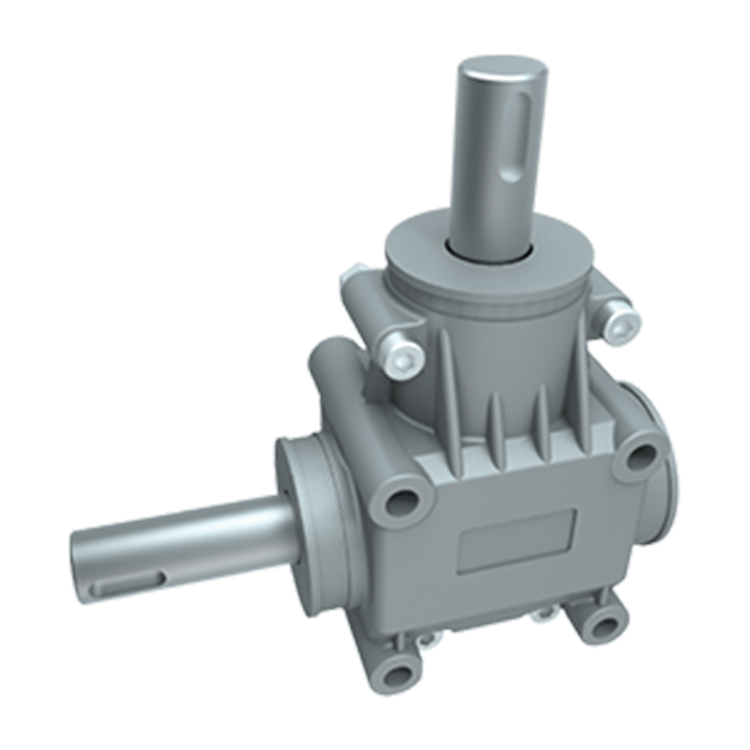

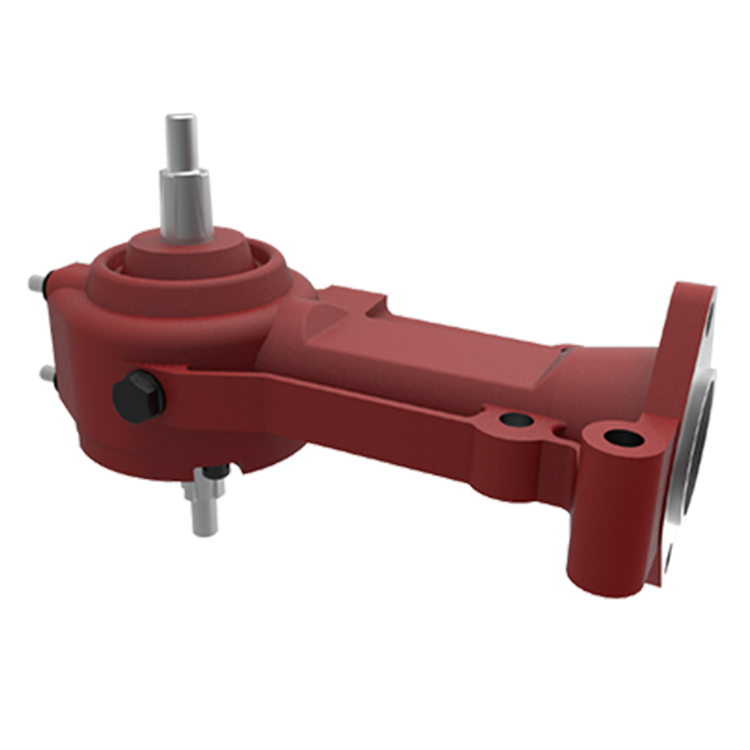

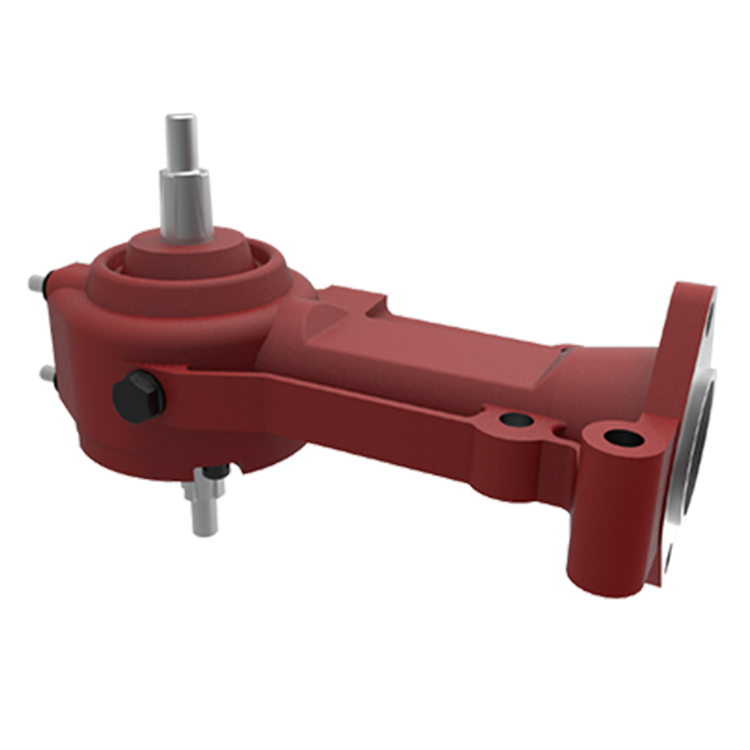

Best China manufacturer & factory Agricultural in Santa Fe Argentina pto 540 tractor gearbox right angel bevel small gear box reducer With high quality best price

We offer OEM service.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant, Machinery Repair Shops, farms, Retail, gearbox for agricultural machinery gear box for ag

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Gearing Arrangement:

-

Bevel / Miter

- Output Torque:

-

0-10000NM

- Input Speed:

-

540

- Output Speed:

-

180-1080

-

Model Number:

Machining of the gearbox To make a worm gearbox, first take a blank of an alloy. A bronze bearing is made in the center of the blank. The hobbing cutter is then used to reduce the diameter of the blank relative to the finished height of the tooth tip on the gear wheel, so the depth of the cut needs to be added to the blank’s diameter. The necessary threading tool is grind to cut the worm. The side clearance on the left-hand side of the cutter tip is allowed for the worm’s pitch angle. The best finish is put on the cutting tool using a slip stone. Gear blank is then mounted on a turntable that acts as a bearing support. This bearing support is mounted on the rear of the lathe cross-slide with the hobbing cutter mounted between the centers. The two worms are then machined, out of which one is made the cutter and finally the cutter is used to machine the worm gear. -

RV10

- Rated Power:

-

0-90KW

Supply Ability

- Supply Ability:

- 100000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- wooden case

- Port

- Shanghai/Ningbo

-

Lead Time

: -

Quantity(Pieces) 1 – 1000 >1000 Est. Time(days) 35 To be negotiated

Online Customization

If you’re looking for a 540 PTO shaft, 540 to 1000 PTO adapter, 540 PTO hydraulic pump, or a 540 PTO gearbox, look no further. It’s important to replace PTO parts that are worn or cracking before you have a major breakdown that could be expensive and even dangerous. We have PTO drive shafts as well as essential shield parts for your safety. Our Eurocardan parts include a range of types of clutches to improve the operation of your power take-off system. PTO shafts and accessories are an important part of the more than 26,000 items we carry for farm, shop, home and garden.

Product Description

Main products include: manure spreading truck, potato planting/harvesting machine, disc plough, disc harrow, grass Mower/slasher, corn and wheat thershers, seeder, mouldboard plow, deep subsoiler machines, rotary tiller, rear blade, fertilizer spreader, combine rice harvester, corn thresher, farm trailer, ridger, trencher, stubble cleaner, earth auger, cultivator and its accessories: Plow disc blades, harrowing film, plough tip and share, cultivator tine, casting parts etc.

The GEARBOXES & DRIVESHAFTS product line is divided into gearboxes (speed change

gears, parallel and right angle shaft speed increasers and reducers), driveshafts and safety

devices mainly employed on agricultural equipments.

Agricultural spreader gearbox for fertilizer spreaders, Saw benches, Belt saws,,MB-550W-15Vertical air compressor,Post hole

digger gearbox OEM-40U 1:1 ratio gearboxes

agricultural gearbox/mixer gearbox/bevel gearbox

|

Contact us |

Related product

Company Profile

Packing & Delivery

Best China manufacturer & factory Brand in Bloemfontein South Africa Tractor Parts Durable Combine Harvester Joint With high quality best price

There is a technical center of province level, EPG academician working station, experiment station for EPG post doctors, and national 863 program set up in EPG group. With these platforms and strong technical ability, the more than 400 technicians have developed all variety of special high precise and high strength products, conducted mold programs for key components in the car and national industry revitalizing program, resulting more than 5000 developed over, among which 33 items are autonomous patent technology with 4 patent approved .

Overview

Quick Details

- Warranty:

-

1.5 years

- Applicable Industries:

-

Manufacturing Plant

- After Warranty Service:

-

Online support

- Local Service Location:

-

none

- Showroom Location:

-

ITALY

- Place of Origin:ZhejiOur company is located in XiHu HangZhou Zhejiang Province. Tang, China

- Brand Name:

-

OEM

- Local Service Location:

-

Italy

- certificate:

-

CE

- Material:

-

Metal

-

We distribute many other items that are not listed above, but are still readily available. Feel free to give us a call or send us an email. We are always ready to help.

- Processing of yoke:

-

Forging

- Design:

-

Customized

- Customized:

-

CE Certificate

Supply Ability

- Supply Ability:

- 20000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- Standard export packing

- Port

- NINGBO OR SHANGHAI

Most commonly, it is a splined drive shaft installed on a tractor or truck allowing implements with mating fittings to be powered directly by the engine.

Online Customization

Product Information

Product Information

PTO Shaft

The power take-off (PTO) is a sophisticated mechanism, allowing implements to draw energy from the engine and transmit it to another application. It works as a mechanical gearbox which can be mounted on the vehicle’s transmission.

The power take-off shaft (PTO shaft) is a critical component, designed and manufactured for continuous heavy-duty use. A good PTO shaft should be strong enough to bear the torsion and shear stress and minimize vibration.

Setforge, the forging subsidiary of Ever-Power Group, manufactures cold extruded PTO shafts for all types of agriculture vehicles. Our PTO shafts offer great dependability and durability during daily use.

EP Group has been internationally recognized as a reliable global supplier. Our state-of-the-art manufacturing process and experienced engineers ensure the top-quality of all Farinia components.

| After Warranty Service | Video technical support |

| Applicable Industries | Manufacturing Plant |

| Local Service Location | Italy |

| Showroom Location | Italy |

| Warranty | 1.5 years |

| Place of Origin | China |

| China | Zhejiang |

| Brand Name | EPG |

| certificate | CE |

| Material | Metal |

| Processing of yoke | Forging |

| Design | Customized |

| Customized | CE Certificate |

Product Display

Product Display

HP21 Skid Steer Au …

PTO Drive Line Gen …

Agricultural Gearb …

CompanyInfo

Company Profile

Ever-Power Group

EPG have high-tech machinery and test equipment. We can produce world class high precision products.

Certifications

Certifications

Shipment & Payment

Our Advantages

A: Your inquiry related to our products or prices will be replied in 24 hours.

B: Protection of your sales area, ideas of design and all your private information.

C: Best quality and competitive price.

……

faq

FAQ

1) How can I place order?

A: You can contact us by email about your order details, or place order on line.

2) How can I pay you?

A: After you confirm our PI, we will request you to pay. T/T (HSBC bank) and Paypal, Western Union are the most usual ways we are using.

……